SOFT ROBOTICS

16 November 2018

Description of the process:

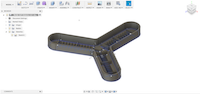

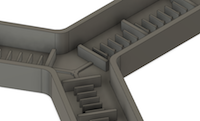

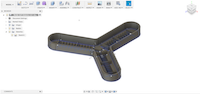

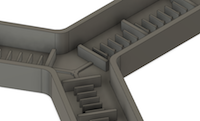

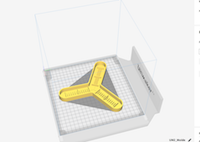

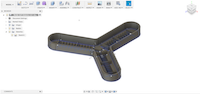

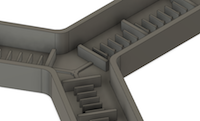

- Design the mold in Fusion 360, using "Extrusion" for making what later will be the air conducts.

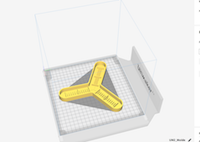

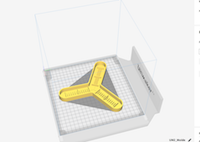

- Trabsfer the file to Ultimaker Cura, to prepare the piece to be 3D printed.

- Print the piece in the 3D printer.

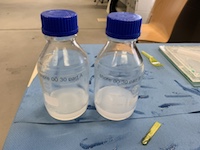

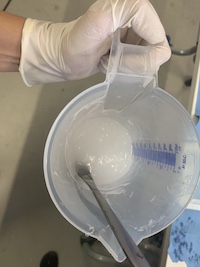

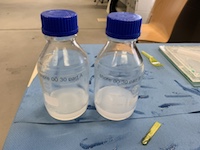

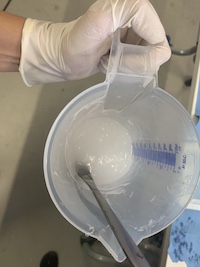

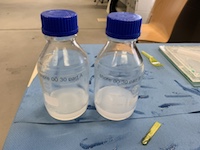

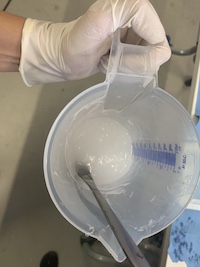

- Mix the components A and B in the same portion.

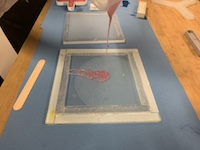

- Spry the mold in order to avoid the material to get sticked on it.

- Put the piece in the oven for 15 minutes.

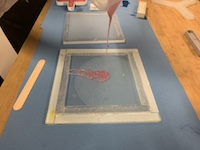

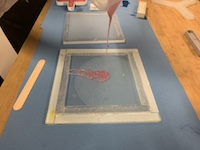

- Prepare a base for the piece using the same components and time in the oven.

- Put the piece and the base together using some more material in the sides.

- Take the final piece, stick a needle in the middle of it and put air in to try the Soft Robotics.

- It didn´t work out as expected because the base didn´t have the same thickness in all of it so the air make bubbles in the thinest parts.